The handling and transfer of powders, granules, and chemical substances in the petrochemical industry present complex challenges due to the abrasive, adhesive, and often corrosive nature of the materials involved, that makes the material handling especially demanding. Safety, stability, corrosion resistance, and system efficiency are critical requirements for any bulk-solids handling solution operating in this sector.

To address these concerns, we deliver highly specialized pneumatic conveying systems and integrated material handling solutions designed for demanding petrochemical environments:

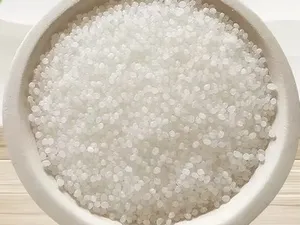

In polyolefin production, product consistency in parameters such as particle size distribution, dust content, and melt index is essential. Our systems incorporate gravity Blender that ensure material uniformity. At the conveying endpoint, elutriators and dedusters remove fine dust and stringy particles from granules, improving final product quality.

Our pneumatic conveying systems are built using corrosion-resistant and high-temperature-tolerant materials, ensuring long-term reliability and reduced maintenance in aggressive chemical environments.

Precise control of conveying pressure and flow rate allows our systems to minimize material loss and prevent leakage during transport, ensuring consistent operation and product quality.

Our bulk-solids handling equipment is engineered with tightly sealed structures capable of withstanding significant pressure differences, enhancing both safety and operational stability.

Intelligent control systems support real-time monitoring and diagnostics. Operators can track system performance remotely, identify abnormalities, and make timely adjustments to maintain safe, efficient operations.

For explosive or flammable materials, we provide ATEX-compliant equipment with integrated inert gas purging systems. Dual-safety instrumentation and certified components ensure compliance with the highest safety standards in explosion-prone zones.

With a focus on high performance, operational safety, and intelligent control, our pneumatic conveying systems are built to meet the rigorous demands of the petrochemical industry and support continuous, high-volume production environments with confidence.

Explore how ShineRay can help streamline your petrochemical material handling process, get in touch with our team today.

PLA (Polylactic Acid)

PLA (Polylactic Acid) PGA (Polyglycolic Acid)

PGA (Polyglycolic Acid) PHA (Polyhydroxyalkanoates)

PHA (Polyhydroxyalkanoates) PCL (Polycaprolactone)

PCL (Polycaprolactone) PVA (Polyvinyl Alcohol)

PVA (Polyvinyl Alcohol) PVC (Polyvinyl Chloride)

PVC (Polyvinyl Chloride) EVOH (Ethylene-Vinyl Alcohol Copolymer)

EVOH (Ethylene-Vinyl Alcohol Copolymer) PS (Polystyrene)

PS (Polystyrene) PMMA (Polymethyl Methacrylate)

PMMA (Polymethyl Methacrylate) PVB (Polyvinyl Butyral)

PVB (Polyvinyl Butyral) PC (Polycarbonate)

PC (Polycarbonate) POM (Polyoxymethylene or Acetal)

POM (Polyoxymethylene or Acetal)

BOPE product upgrade project pneumatic conveying system- Tianjin Petrochemical

100,000 tons/year UHMWPE Project complete silo and homogenizing system

LDPE conveying system retrofit

200,000 tons/year HDPE Project- Jianguang

Comprehensive solution including pneumatic conveying system, silos, and additive handling systems

400,000 tons/year PVC pneumatic conveying system

300,000 tons/year PLA pneumatic conveying, gravity blending, and dedusting system

1,000,000 tons/year PS pneumatic conveying system

310,000 tons/year ABS/PS pneumatic conveying and silo system for SP Chemicals

Manual bag dump station for Shanghai DSM

Pneumatic conveying systems are suitable for a wide range of powder and granular materials in chemical production. These include various polyolefins such as PP, PE, POE, EVA, as well as chemical raw materials, additives, catalysts, intermediates, and finished products.

Due to the corrosive nature of many chemical substances, our conveying systems utilize corrosion-resistant materials such as stainless steel and engineered plastics. Surface treatments are also applied to enhance durability and ensure long-term, stable operation in harsh environments.

For flammable or explosive chemicals, our systems use inert gases such as nitrogen as the conveying medium to eliminate combustion risks. Optional gas recovery units enable collection, pressurization, and reuse of inert gases, reducing operational costs. Additional safety features include explosion-proof instruments, electrostatic grounding, safety valves, and rupture discs to ensure safe and reliable operation.

Dust collectors and dedusting units are critical for preventing contamination and maintaining product quality. Baghouse dust collectors minimize emissions from exhaust air, protecting both the environment and workplace air quality. Dedicated dedusting units remove fine dust, streamers, and fiber-like contaminants from loose bulk-solids, making them ideal for polymer reprocessing applications.

Efficiency can be enhanced by optimizing system layout and design:

There are two main types of pneumatic conveying: pressure conveying and vacuum conveying. Pressure conveying pushes material through the pipeline using compressed air, while vacuum conveying draws material toward the destination. Both methods are suitable for plastic pellet transfer. The choice between them depends on your plant layout, material properties, and system requirements. Additionally, it is crucial to determine whether to use dilute-phase or dense-phase conveying, depending on factors like particle fragility, flow rate, and conveying distance.

Yes, pneumatic conveying is well-suited for handling delicate resin materials. Because the process involves minimal mechanical contact with the material, it helps reduce the risk of degradation or damage during transfer. This makes it ideal for preserving the quality of sensitive resins throughout the production process.

Have a question or project in mind? Send us a message and our team will get back to you promptly.