ShineRay (XRIE) operates a dedicated R&D center along with an independent testing laboratory, both focused exclusively on bulk-solids handling technologies. The facility is equipped with a wide range of in-house testing platforms, including dense phase plug flow/dilute phase pneumatic conveying systems, setups for viscous and nano powder transfer, dust collection system prototypes, precision weighing and dosing modules, as well as manual and automatic bag unloading systems for both small and bulk bags.

These testing systems enable us to conduct thorough testing on customer-provided materials across various industries. The resulting data is accurate, application-specific, and serves as a reliable foundation for engineering design, ensuring each system performs as expected from the start. This minimizes the risk and cost associated with investing in new bulk-solids handling installations.

The dedusting process in pneumatic conveying systems is essential for maintaining efficient operation and ensuring clean air within the production environment. It is widely applied in industries such as chemicals, food, pharmaceuticals, and plastics. During conveying, fine dust particles generated or carried by the material may be released into the airstream. Through the use of specialized equipment and processes, these particles are separated and removed to prevent dust accumulation, protect equipment, reduce environmental pollution, and ensure operator safety.

In pneumatic conveying systems, materials are transported through pipelines under the push of airflow. During this process, fine particles may become airborne and enter the exhaust stream. To ensure the cleanliness and safety of the system and prevent dust from escaping into the environment, air treatment through dedusting equipment is required.

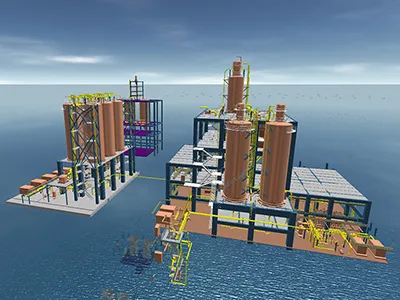

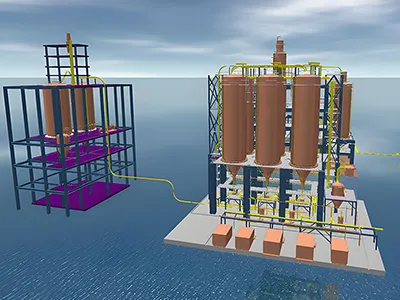

Before homogenization and after homogenization

Before homogenization and after homogenization

ShineRay (XRIE) operates a fully equipped physical property testing center designed to assess the behavior and characteristics of bulk-material across various industries. The facility features a wide range of specialized instruments, including multifunctional powder testers, friction angle testers, moisture analyzers, particle size distribution analyzers, silo cone outlet and angle testers, and fluidization pressure drop testers. These tools allow for comprehensive evaluation of material properties and flow behavior, such as particle size distribution, angle of repose, bulk density, true density, Carr flowability index, and volatile content. All test data are highly accurate and serve as a critical foundation for engineering design, ensuring each system performs as intended from the outset. By basing design decisions on precise material testing, ShineRay helps clients reduce the risk and cost associated with investing in new powder handling installations.

Mechanical balance

Mechanical balance Multi-function testing machine

Multi-function testing machine Powder property analyzer

Powder property analyzer

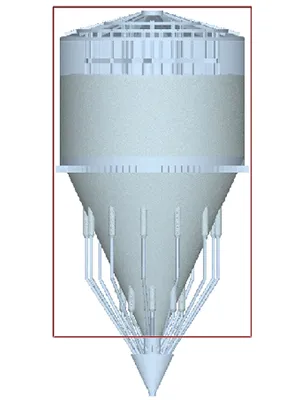

Filled fully with powder

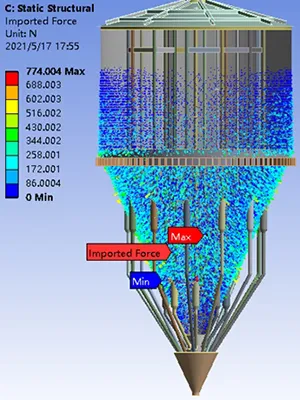

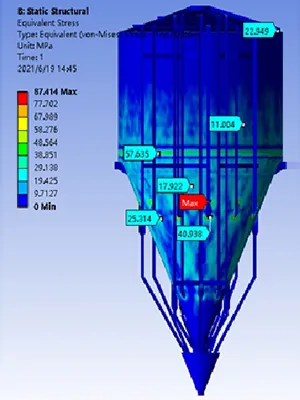

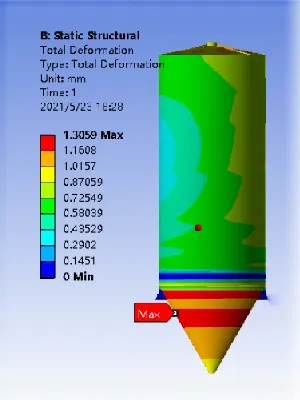

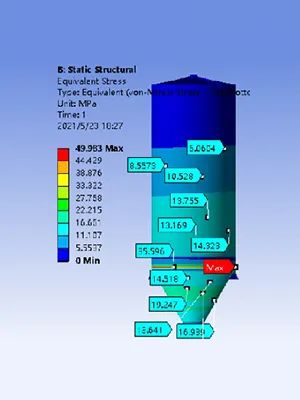

Filled fully with powder Load analysis

Load analysis Structure analysis & optimization

Structure analysis & optimization

Get in touch to talk about how we can support your production goals.