Pneumatic conveying is a method of transferring bulk-solids such as powders and granules from one or more feed points to designated destinations using pressurized airflow or mechanical energy through enclosed pipelines. Throughout the conveying process, additional functions such as weighing and dosing, blending or separation, bag opening, material loading/unloading, and dust collection can be seamlessly integrated to support fully automated and clean material handling operations.

We provide tailored design and construction services for pneumatic conveying systems across a wide range of industries. Our systems are engineered to handle the specific requirements of various powdered and granular materials.

Key application sectors include:

If you require a customized pneumatic conveying solution tailored to your process needs, feel free to Contact Our engineering team for consultation.

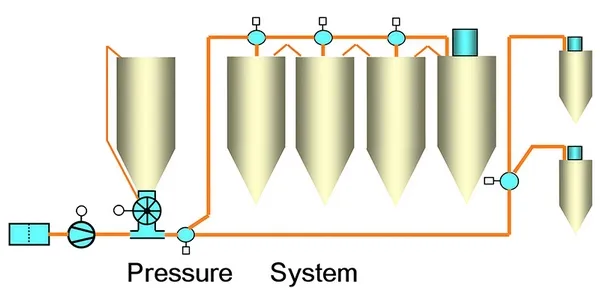

Positive pressure pneumatic conveying system is primarily suitable for transporting materials from a single feeding unit to multiple receiving hoppers. It allows higher solids loading ratio and requires smaller pipeline diameters and equipment footprint compared to vacuum conveying systems.

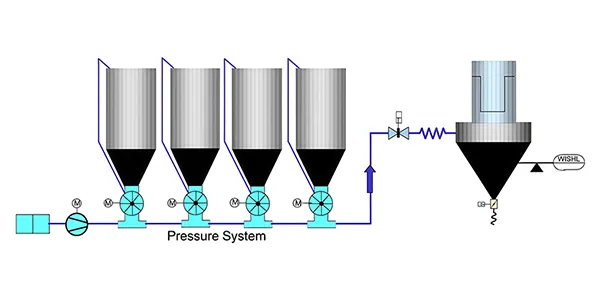

Vacuum conveying system is ideal for conveying materials from multiple feeding units to one receiving unit. The conveying pressure is typically limited to approximately -0.5 bar.

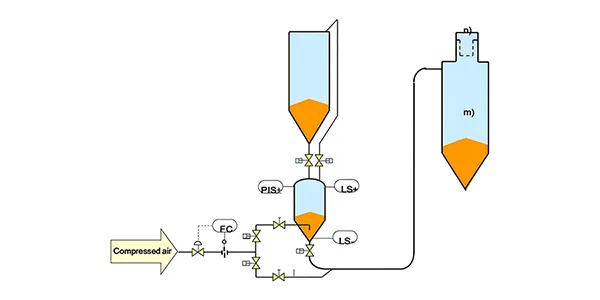

Easy control, and conveying pressure can reach up to 3 bar

High pressure resistance and good sealing performance, suitable for long-distance large-capacity conveying, and conveying pressure can reach up to 6 bar

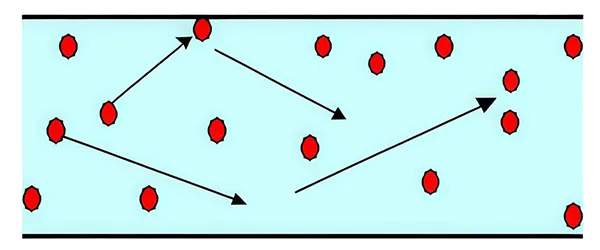

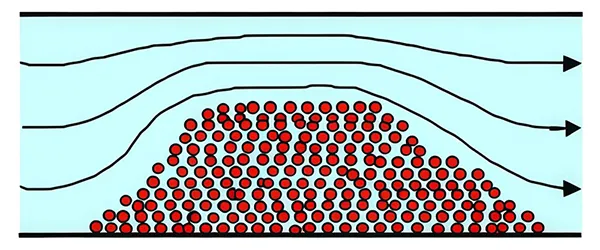

Materials are almost uniformly distributed across the pipeline cross-section. The solids loading ratio is low and the conveying speed is relatively high.

Materials fill most or all of the pipeline cross-section. The solids loading ratio is high and the conveying speed is relatively low.

Have a question or project in mind? Send us a message and our team will get back to you promptly.

At the feeding point, bulk-solids are introduced into a stream of high-velocity gas. The gas exerts drag force on the particles, overcoming gravity, friction, and inertia, allowing the material to move in either a suspended (dilute-phase) or slug-like (dense-phase) form through enclosed pipelines. Upon arrival at the destination, the material is separated from the air via centrifugal force, filtration, or velocity reduction. The purified gas is either exhausted or recirculated, and the conveyed material is collected in storage bins or containers.

Pneumatic conveying systems offer exceptional layout flexibility, allowing pipelines to navigate around obstacles and utilize vertical and horizontal space effectively, ideal for complex plant layouts. They also provide more freedom in choosing feeding and discharge locations. The system design is relatively simple with fewer moving parts, leading to lower equipment costs and easier maintenance, particularly for long-distance and high-volume transfer needs.

Yes. Pneumatic conveying systems are highly adaptable and can be integrated into existing plant layouts with ease. Compared to mechanical systems, they require less floor space and can be routed around or above existing structures such as ceiling beams, trusses, or other process piping, making them ideal for retrofit applications.

These systems have lower operating and energy costs and require minimal maintenance due to fewer mechanical components. They can also be designed for easy disassembly and cleaning, enabling fast sanitation turnarounds. In contrast, mechanical systems often have more integrated components that are harder to clean and maintain.